Why Choose ZW Group Asphalt Tanker Trailer?

With over 10 years of experience designing and exporting asphalt tanker trailers and related transport equipment, Shandong ZW Vehicle Group has built a strong reputation in more than 60 countries. As a result, our trailers are trusted globally for durability, heat resistance, and reliable performance under various road and weather conditions.

At our 50,000m² advanced facility in Shandong, production combines CNC cutting systems, automated welding, and precision assembly lines. In addition, over 200 skilled technicians ensure that every asphalt tanker trailer meets strict international standards for safety, corrosion resistance, and long-term reliability.

Moreover, each trailer is designed for efficient transport of asphalt, fuel, or chemicals. Consequently, operators benefit from stable handling, reduced operating costs, and excellent load capacity. By integrating carbon steel or stainless steel tanks with reinforced chassis construction, we achieve both strength and durability for demanding applications.

Furthermore, our rigorous quality control process—from raw material inspection to final shipment—ensures every trailer performs reliably worldwide. Therefore, whether used as a fuel tanker trailer, chemical tanker trailer, or LPG trailer, ZW Group asphalt tanker trailers provide safe, efficient, and cost-effective liquid transport.

Safe and Efficient Loading of Asphalt into an Asphalt Tanker Trailer

Proper loading of asphalt into an asphalt tanker trailer is crucial for safety and efficiency. First, ensure the trailer is parked on level, stable ground near the heating and filling station. This setup prevents unwanted movement or imbalance during loading.

Next, connect the trailer’s top or bottom loading port to the supply line using high-temperature-resistant hoses and fittings suitable for asphalt. Also, carefully inspect all connections to prevent leaks or spillage, which could create safety hazards.

Then, activate the pump or gravity-fed loading system as required. At the same time, monitor the flow rate, tank temperature, and internal pressure. Maintaining these parameters within safe limits is essential, since asphalt must remain at optimal temperature to flow properly and avoid hardening.

As the tank nears full capacity, gradually reduce the loading rate. This prevents splashing, overfilling, or excessive pressure buildup. Finally, after loading is complete, close all valves securely, disconnect the hoses carefully, and check safety vents, manholes, and seals to ensure the trailer is ready for transport.

By following these steps, operators can maintain a controlled, safe, and efficient asphalt loading process. Consequently, both the cargo and the asphalt tanker trailer are protected, ensuring optimal performance and reliability for every ZW Group asphalt tanker trailer.

Technical Specifications

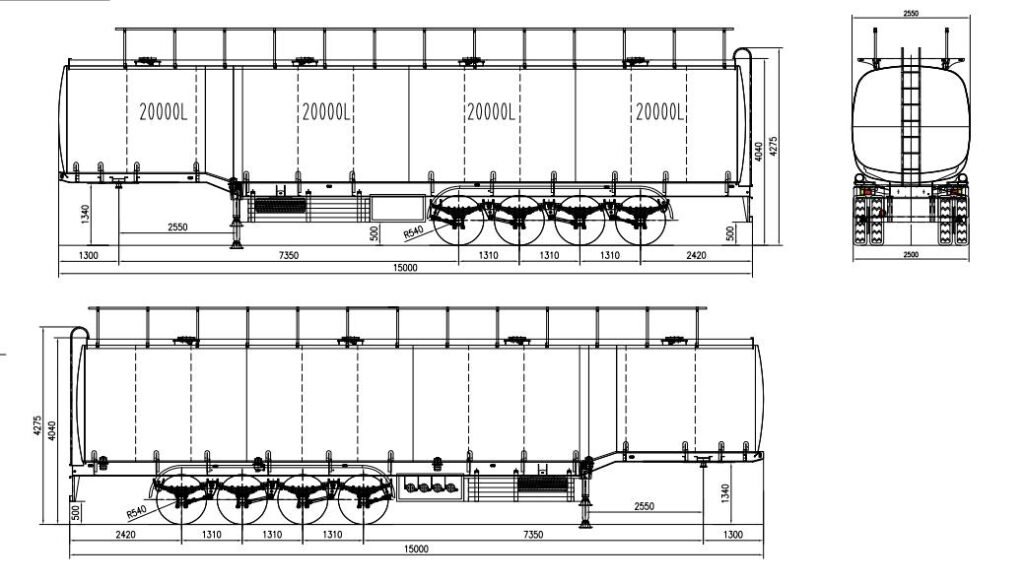

4-Axle Asphalt Tanker – Technical Design

3-Axle Single-Compartment Oil Tanker Trailer – Design Drawing

.png)

3-Axle Single-Compartment Oil Tanker – Design Version 2

-1024x512.jpg)

Three-Compartment Oil Tanker Trailer (3 Axles) – Technical Design

.jpg)

Packaging & Global Shipping

At Shandong ZW Vehicle Group, every asphalt tanker trailer is carefully inspected, securely packaged, and reinforced to ensure safe international transport. First, each unit undergoes a thorough quality check. If necessary, partial assembly with extra fastening is applied to minimize transit risks.

Next, trailers can be shipped via container, Ro-Ro (Roll-on/Roll-off) vessels, or flat rack/open deck transport. This depends on customer needs and port conditions. Such flexibility guarantees that each asphalt tanker trailer reaches its destination safely and efficiently.

Moreover, our experienced logistics team works closely with trusted global freight partners. They handle every aspect of transportation, including inland hauling, port coordination, and customs clearance.

As a result, these customized shipping solutions provide a smooth, worry-free delivery experience. From start to finish, ZW Group ensures that every asphalt tanker trailer arrives on time, secure, and ready for operation anywhere in the world.

Tanker Trailer Parts

The ZW Group Asphalt Tanker Trailer is expertly designed with key components that ensure durability, safety, and efficient transport of asphalt and other bituminous liquids. Consequently, it is ideal for fuel, chemical, and industrial liquid applications across global logistics operations.

1. Asphalt Tank

First, the high-quality carbon steel or stainless steel tank is engineered for heat retention and corrosion resistance, reducing material loss and extending service life. Additionally, the smooth internal finish simplifies cleaning and minimizes contamination risks.

2. Chassis Frame & Main Beam

Moreover, the reinforced steel or aluminum chassis incorporates a precision-engineered main beam, providing superior structural strength, balanced weight distribution, and resistance to bending or torsion. Advanced welding and anti-corrosion treatments ensure stable performance under heavy or uneven loads.

For secure and efficient tractor-trailer coupling:

Standard Fifth Wheel Coupling: Equipped with JOST 50# active-type couplings for reliable attachment.

Optimized Kingpin Height (~1,390 mm): Ensures smooth towing and balanced weight distribution.

Robust Landing Gear: JOST 25-ton linked legs provide solid support during loading and unloading.

Integrated Electrical & Air Connections: Seamless integration with tractor lighting and pneumatic brake systems.

Customizable Fit: Trailer design can be adapted for specific tractors or operational requirements.

These features guarantee the chassis offers a solid foundation for safe, smooth, and efficient trailer operation in diverse asphalt transport environments.

3. Axles & Suspension

The multi-axle air suspension system delivers a smooth ride, balanced weight distribution, and enhanced handling, suitable for both highways and rough terrain.

4. Thermal Insulation (Optional)

Optional insulation or heating systems maintain asphalt at optimal temperatures, preventing solidification or viscosity changes during long-distance transport.

5. Loading & Discharge Equipment

High-efficiency valves and leak-proof manholes allow fast, safe, and spill-free loading and unloading, maximizing operational efficiency and safety.

6. Braking System

A reliable air brake system provides responsive control and precise stopping power, fully compliant with international safety standards.

7. Lighting & Visibility

LED tail lights, side markers, and reflectors enhance visibility during night or low-light operations, ensuring compliance with global transport regulations.

8. Toolbox & Accessories

Integrated tool compartments and safety equipment allow easy access to maintenance tools and emergency gear, supporting safe and efficient on-road operations.

Manufacturing Display

At Shandong ZW Vehicle Group, we combine advanced manufacturing technology with expert craftsmanship to produce high-quality asphalt tanker trailers. Our 50,000m² facility features CNC cutting machines, robotic welding systems, and precision assembly lines, ensuring accurate and efficient production for liquid asphalt transport.

From raw material selection to final assembly, every asphalt tanker trailer undergoes strict quality inspections at each stage, guaranteeing durability, safety, and optimal performance for both short- and long-distance transport. Our team of over 200 skilled professionals continuously innovates to maintain high standards.

We utilize premium-grade carbon steel and stainless steel materials, sourcing components from trusted global suppliers. As a result, each trailer meets or exceeds international standards for asphalt, chemical, fuel, and other industrial liquid transport.

By integrating advanced technology, skilled workmanship, high-quality materials, and strict quality control, ZW Group reliably delivers asphalt tanker trailers that ensure safe, efficient, and high-performance operations for global customers.

Client Insights

Our customers consistently commend the durability, reliability, and versatility of our asphalt tanker trailers. They particularly note the smooth handling, safe operation, and robust construction, which together support efficient asphalt transport across roads, highways, and construction sites.

In addition, many clients value the low maintenance requirements, which help minimize downtime and enhance overall operational productivity. Consequently, these advantages contribute to strong return on investment and dependable performance, establishing our asphalt tanker trailers as a trusted choice in global markets.

Moreover, ZW Group remains dedicated to continuous improvement, ensuring that every asphalt tanker trailer meets evolving industry standards and the diverse expectations of customers worldwide.

Global Delivery Highlights

Over the years, ZW Vehicle Group has reliably delivered asphalt tanker trailers to clients across numerous countries, thereby establishing a strong reputation for consistent performance and durability. Each trailer is specifically engineered to endure demanding operating conditions—whether on highways, construction sites, or industrial zones.

Moreover, customers often highlight the trailers’ excellent handling of asphalt and other viscous liquids, ensuring smooth operation and dependable service over long-term use.

In addition, every shipment is meticulously prepared, with careful adherence to safety procedures, comprehensive quality inspections, and secure packaging, guaranteeing that each trailer arrives in perfect condition.

Consequently, these proven delivery records not only demonstrate our commitment to customer satisfaction but also underscore ZW Group’s position as a trusted global partner for safe, efficient, and reliable asphalt transport.

FAQ

Q1: What types of asphalt can the trailer carry?

A1: Hot mix asphalt, bitumen, and other viscous road materials.

Q2: Are trailers insulated or heated?

A2: Optional insulation or heating keeps asphalt at optimal temperature.

Q3: How many axles do the trailers have?

A3: Available in 3-axle or 4-axle configurations.

Q4: Can the trailers be customized?

A4: Yes, tank size, insulation, and loading systems can be tailored.

Q5: How is safe loading and unloading ensured?

A5: Leak-proof manholes and high-efficiency valves enable spill-free handling.

Q6: Do you ship worldwide?

A6: Yes, via container, Ro-Ro, or flat rack, managed by our logistics team.

Get a Free Quote