Fuel Tanker Trailer Full Guide

ZW Group| 2025-11-25

What Is a Fuel Tanker Trailer?

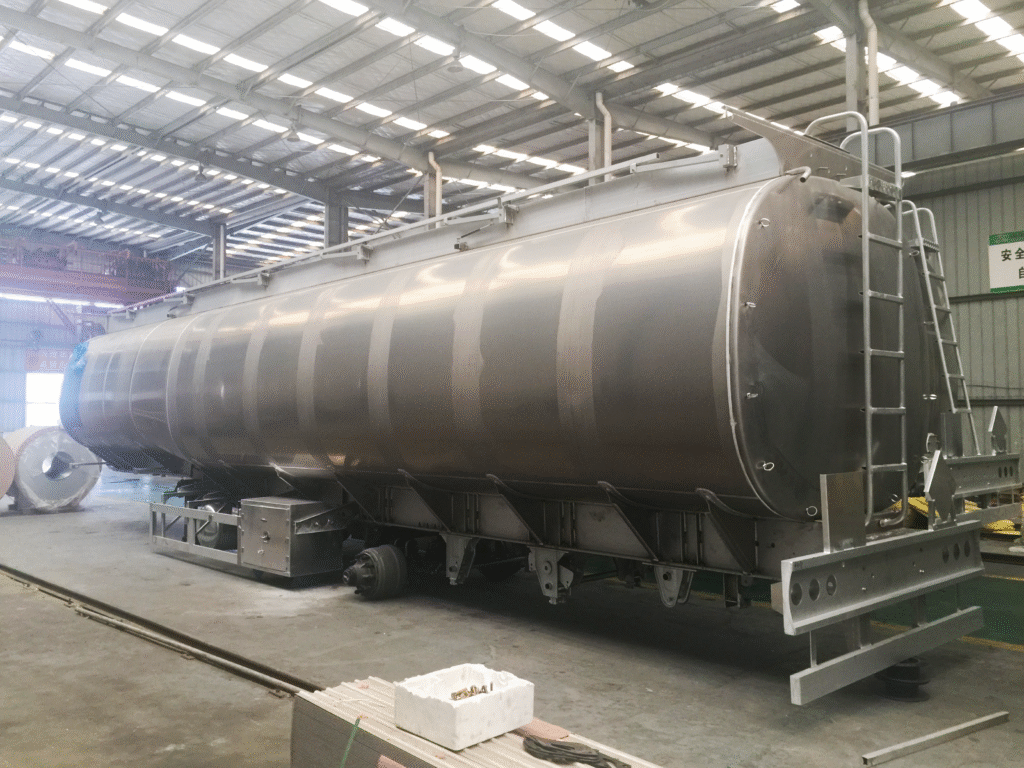

A fuel tanker trailer is a specialized semi-trailer designed for safe and efficient bulk transportation of liquid fuels, including diesel, gasoline, kerosene, and lubricants. Unlike generic transport vehicles, these trailers must comply with strict safety standards to prevent leaks, spills, or accidents.

At ZW Group, every tanker is engineered with precision welding, corrosion-resistant coatings, and rigorous pressure testing, ensuring a long service life. These trailers are used by fuel distributors, logistics companies, industrial plants, and construction operations worldwide.

1. Tank Materials and Manufacturing Process

Fuel tanker trailers are commonly made from:

Carbon steel: high strength, cost-effective, ideal for diesel and petrol

Stainless steel 316L: corrosion-resistant, perfect for chemical fuels

Aluminum alloy: lightweight for long-distance transport, improving fuel efficiency

Inside the factory, each tank undergoes:

Robotic or manual welding for structural integrity

Anti-corrosion coating for harsh climates

Pressure and leak tests to ensure compliance with ADR/DOT standards

[Internal Link Placeholder 1 – “What Is a Powder Tanker Trailer?”]

This manufacturing precision ensures that ZW Group trailers maintain reliability even under challenging operational conditions.

2. Compartment Design and Structure

Modern fuel tankers often have 2–7 compartments. Key structural features include:

Anti-surge baffles to reduce liquid movement

Bottom or top loading valves depending on regional preferences

Manholes with fire-resistant covers

Multi-compartment tanks allow transportation of different fuel types in one trip, improving fleet efficiency and safety.

3. Safety Features and Compliance

Critical safety components include:

Emergency shut-off valves

Anti-static grounding systems

Pressure relief and overfill prevention valves

These configurations make the trailers suitable for Class 3 hazardous fuels and compliant with international regulations.

4. Market Applications and Regional Insights

ZW Group fuel tanker trailers serve:

Urban and rural fuel distribution networks

Mining and construction fuel supply

Industrial logistics and plant operations

In Africa and the Middle East, operators often request:

Larger capacities (30,000–45,000 liters)

Bottom-loading systems for safe and efficient operation

Multi-compartment designs to meet local regulations and fuel station infrastructure

This tailored approach ensures that the trailers meet regional operational requirements while maintaining high safety and performance standards.

5. Cost, Lifespan, and ROI

A well-maintained fuel tanker trailer can last 6–12 years. Material choice affects cost and lifespan:

Carbon steel: cost-effective, good for standard fuels

Stainless steel: ideal for chemical or high-grade fuels, higher durability

Choosing the right material, compartment design, and safety configuration improves fleet ROI and reduces downtime.

6. Conclusion

A fuel tanker trailer is essential for safe, efficient bulk fuel transportation. By combining professional manufacturing, advanced safety systems, and region-specific adaptations, operators can optimize fleet performance while ensuring compliance. Understanding both the technical specifications and practical applications is key for businesses seeking reliable fuel transport solutions.